RoboBallet Enhances Robotic Arms Collaboration

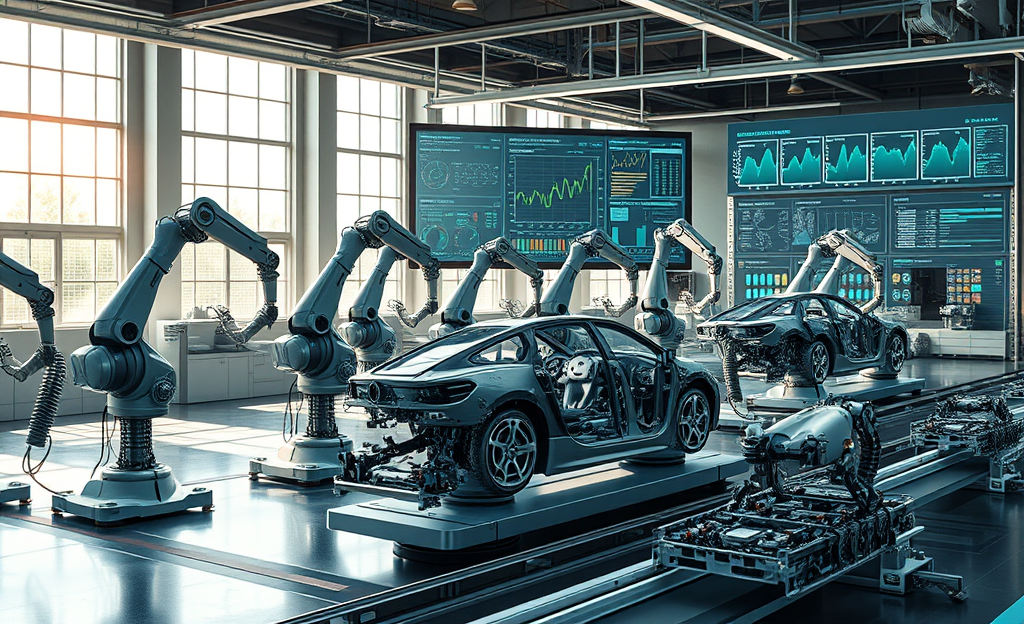

Robotic Arms have become a cornerstone of modern industrial automation, revolutionizing the way factories operate.

In this article, we explore RoboBallet, a pioneering AI algorithm that streamlines the collaboration of these robotic systems.

By employing advanced technologies like graphical neural networks and reinforcement learning, RoboBallet automates movement and task planning, significantly reducing the need for manual programming.

We will delve into its capabilities, applications across various industries, and the future vision for this innovative software, providing insights into how it can transform manufacturing processes.

RoboBallet: Revolutionizing Industrial Robotics Coordination

Introducing RoboBallet, a groundbreaking AI algorithm that transforms the coordination and efficiency of robotic arms within industrial settings.

This intelligent system harnesses cutting-edge technologies such as graphical neural networks and reinforcement learning to revolutionize how movements and tasks are planned in factories.

By automating the task planning process, RoboBallet significantly reduces the need for manual programming, thereby accelerating operational speeds and enhancing productivity across diverse factory scenarios.

Its speed and precision allow it to manage intricate layouts involving up to eight robotic arms and coordinate up to 40 tasks seamlessly.

Furthermore, its intelligent adaptation makes it highly versatile and applicable to a broad spectrum of sectors, from automobile manufacturing to electronics assembly, as highlighted in this Insightful article on RoboBallet.

As this technology continues to evolve, RoboBallet stands poised to define the future of automated industrial choreography.

Core Technologies Behind RoboBallet

The core technologies behind RoboBallet harness the power of graphical neural networks and reinforcement learning to revolutionize robotic collaboration in industrial settings.

Graphical neural networks enable the system to interpret complex factory layouts, allowing for efficient planning and execution of robotic movements.

Coupled with reinforcement learning, RoboBallet optimizes its strategies over time, rapidly generating high-quality movement plans that adapt to varying tasks and conditions.

Graphical Neural Networks

Graphical Neural Networks (GNNs) play a crucial role in industrial robotic planning by effectively modeling the spatial relationships between multiple robotic arms.

This capability allows RoboBallet to dynamically reason about the positioning of obstacles and automate the orchestration of complex tasks.

By employing GNNs, RoboBallet transcends traditional manual programming to generate efficient movement plans rapidly.

This system’s adaptability enables seamless collaboration in the industrial environment, optimizing workflows and reducing downtime.

For more information on this technology, you can explore Graph Neural Networks for Decentralized Path Planning.

The result is a versatile solution capable of elevating productivity across various sectors.

Reinforcement Learning

Reinforcement learning significantly enhances RoboBallet’s action sequences by employing reinforcement learning techniques.

This advanced methodology optimizes movement strategies through a meticulous process of simulated trial-and-error, which allows robotic systems to learn and adapt over time, resulting in swifter and safer execution paths.

By continuously iterating on movement plans, reinforcement learning not only improves speed and efficiency but also minimizes potential risks, ensuring enhanced safety protocols are adhered to during operations.

These key benefits translate to tangible improvements in sectors utilizing RoboBallet, such as automobile manufacturing and electronics assembly, where enhanced safety and efficiency are paramount.

Capabilities and Industrial Applications

RoboBallet stands out with its exceptional capability to orchestrate up to 40 intricate tasks using eight robotic arms simultaneously.

This unparalleled efficiency transforms complex industrial operations, minimizing the time traditionally required for manual programming by leveraging advanced technologies like graphical neural networks and reinforcement learning.

With this proficiency, RoboBallet holds significant advantages in key sectors, where rapid and precise robotic coordination is paramount.

Particularly, its impact is profound in industries such as:

- Automobile manufacturing

- Electronics assembly

- Construction

By facilitating tasks from welding to assembly, the system enhances productivity and reduces operational costs.

Furthermore, its open-source release fosters continual advancements.

RoboBallet AI revolutionizes these sectors by allowing seamless integration into existing factory workflows, thus stepping towards more autonomous and intelligent factory environments.

Adapting such a groundbreaking approach addresses current industry demands and opens avenues for more sophisticated applications in future iterations.

Current Focus and Future Directions

RoboBallet leverages cutting-edge AI to transform robotic arm collaboration in industrial settings by optimizing movement tasks.

Currently, its primary focus lies in enhancing movement efficiency through graphical neural networks and reinforcement learning.

This allows the system to generate precise and collision-free movement plans in complex environments, managing up to eight robotic arms and forty tasks simultaneously.

Despite its impressive performance, RoboBallet’s present capabilities are limited to movement tasks, leaving intricate task dependencies as future challenges.

Planned enhancements aim to expand the system’s functionality, enabling it to tackle more complex operations and affect task dependencies more effectively.

As RoboBallet’s capabilities evolve, it promises profound impacts on diverse sectors from automobile manufacturing to electronics assembly.

The open-source availability of RoboBallet further encourages innovation and research, fostered by communities working together to enhance robotic collaboration.

RoboBallet features continue to promise new advancements in automation.

Limitations and Open Source Contribution

RoboBallet is an innovative AI algorithm that seamlessly orchestrates robotic arms in industrial settings.

However, it faces limitations, particularly in managing task dependencies effectively and handling all factory scenarios.

The system’s current iteration, although capable of optimizing movement tasks, does not yet address scenarios requiring intricate task sequencing.

Despite these limitations, RoboBallet’s open-source release significantly contributes to research and development within the realm of industrial automation.

By making its source code public, it encourages collaborative improvements and customization, enabling the community to address existing constraints and innovate new functionalities.

This open-source model fosters great potential for adaptations, ensuring that RoboBallet evolves with industry needs.

For a concise overview, consider the table below:

| Limitation | Open Source Advantage |

|---|---|

| Cannot yet manage task dependencies | Community-driven improvement |

By embracing open-source contributions, RoboBallet not only aims to overcome its current challenges but also anticipates its future role in the evolution of intelligent manufacturing solutions.

In conclusion, RoboBallet represents a significant advancement in the field of industrial automation, particularly for robotic arms.

With its open-source platform and future enhancements, it promises to address current limitations and further optimize factory operations.

0 Comments