Revolutionizing Robotics with RoboBallet AI System

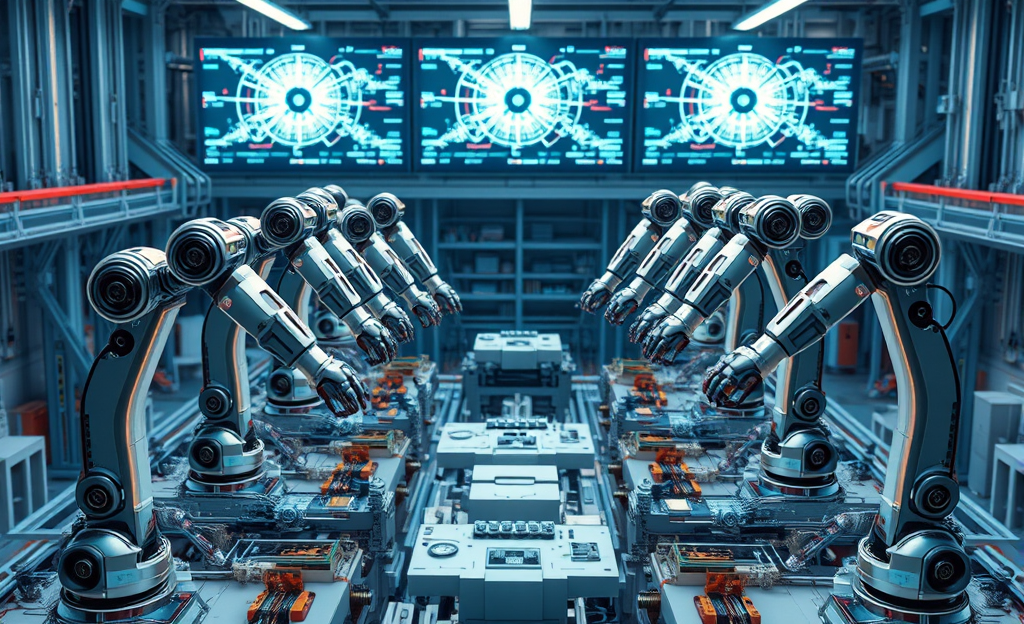

Robotics Revolution is upon us with the advent of innovative technologies like RoboBallet, an AI algorithm designed to enhance the cooperation of robotic arms in industrial settings.

This article delves into how RoboBallet leverages graphical neural networks and reinforcement learning to optimize robotic movements, streamline processes, and improve efficiency within factories.

By enabling rapid, intelligent coordination among multiple robots, this groundbreaking project aims to transform the landscape of industrial robotics, adapting seamlessly to challenges and evolving operational needs.

RoboBallet: Innovative AI for Coordinated Robotics

RoboBallet stands as a revolutionary force in the realm of industrial robotics, driven by an ingenious combination of graphical neural networks and reinforcement learning.

This advanced AI algorithm orchestrates the seamless collaboration of multiple robotic arms in factory settings, presenting a transformative leap in automation technology.

Engineered to work with DeepMind’s RoboBallet expertise, the system excels in generating high-quality plans in mere seconds.

Addressing up to 40 tasks with eight robots simultaneously, its sophisticated logic ensures an optimized flow that minimizes delays.

The system delivers impressive speed while ensuring safe operation, featuring a keen aptitude for collision avoidance and efficiency.

RoboBallet empowers factories to rapidly adapt to changing scenarios, such as equipment failures or new production layouts, thereby bolstering operational resilience.

While tackling complex layouts is its forte, it also promises ongoing improvements with future versions to handle specialized task sequences.

Ultimately, RoboBallet encapsulates the future of industrial efficiency, enabling a new dance of robotic coordination to take center stage in manufacturing environments worldwide.

High-Speed, High-Quality Motion Planning

RoboBallet revolutionizes industrial robotics with its sophisticated AI algorithm, enabling unparalleled efficiency in motion planning.

Utilizing cutting-edge graphical neural networks and reinforcement learning, RoboBallet expertly orchestrates eight robotic arms to tackle up to 40 complex tasks within seconds.

Each robot’s movement is automatically planned to avoid collisions, ensuring a seamless and synchronized operation.

By achieving this, factories not only prevent potential downtime but also enhance productivity exponentially.

RoboBallet’s ability to generate these high-quality plans in seconds stems from its intelligent planning strategy, which efficiently devises robot movements even amidst intricate layouts.

This system elevates the factory floor’s adaptability, allowing immediate responses to operational changes or unexpected failures.

As a result, industries experience minimized delays and optimized workflow management.

Moreover, the open-source nature of RoboBallet’s code invites continuous collaboration and innovation, further accelerating advancements in industrial automation.

Explore more about RoboBallet’s impact in transforming the future of robotics.

Together, these elements make RoboBallet an unprecedented tool, redefining the limitations of conventional manual programming.

Transforming Factory Flexibility and Efficiency

RoboBallet revolutionizes industrial robotics by granting factories the ability to quickly adjust to any disruptions or changes.

This advanced AI system, utilizing a graphical neural network combined with reinforcement learning, can instantly reconfigure workflows when a robot fails, ensuring continuous operation.

By automatically planning the movements of robots and optimizing their paths to avoid collisions, RoboBallet enhances efficiency gains throughout production lines.

Furthermore, the system effectively addresses up to 40 tasks involving eight robots in complex layouts, generating high-quality plans in mere seconds.

Its ability to efficiently adapt robot positioning not only increases throughput but also maximizes factory flexibility.

Although current limitations exist, such as handling tasks needing specific sequences, RoboBallet’s open-source code invites ongoing improvements to tackle these challenges.

This innovative system ultimately transforms factory adaptability by providing a resilient, dynamic response to equipment failures, seamlessly optimizing production processes and enhancing overall productivity.

Factories leveraging RoboBallet can maintain high efficiency levels, ready to embrace future developments and maximize their operational potential.

Current Limitations and Future Prospects

RoboBallet represents a significant leap forward in industrial robotics, yet it faces current constraints that are particularly apparent in executing tasks needing specific sequences.

Sequence-dependent operations remain challenging because the current algorithm does not completely account for tasks that require strict sequential order, such as certain assembly processes prevalent in manufacturing.

This limitation can hinder the overall efficacy of multi-robot coordination, leading to potential delays or inefficiencies in production lines.

However, future potential for the system is immense.

Researchers are actively working to enhance RoboBallet, envisioning future updates that incorporate advanced sequencing algorithms.

These improvements promise to transform RoboBallet by allowing it to adapt seamlessly to complex, order-specific tasks, thereby dramatically increasing its utility in a broader array of industrial applications.

According to a publication on [Graph Policy Neural Networks with Reinforcement Learning](https://pubmed.ncbi.nlm.nih.gov/40901976/), ongoing advancements are set to enable task sequencing capabilities.

Upcoming updates promise solutions that will render RoboBallet more adept at handling these intricacies, driving further innovation and efficiency in robotic automation.

Open Source Release Accelerates Innovation

Releasing RoboBallet’s code as open source is a strategic decision that propels the collaborative innovation in AI-driven industrial robotics.

With public code access, developers and researchers worldwide can contribute to enhancing RoboBallet’s capabilities, unlocking doors to collective intelligence and skill-sharing across global communities.

This openness encourages faster research cycles, enabling rapid prototyping and implementation of improvements, thus driving progress in a field where cross-industry insights are essential.

Moreover, open sourcing provides a fertile ground for experimentation, allowing diverse teams to tailor and customize the tool for various industrial applications, thereby solving unique operational challenges.

This collaborative spirit not only ensures a continual evolution of the technology but also democratizes access to cutting-edge solutions, fostering an ecosystem where all parties benefit.

According to resources from RoboBallet system development, such releases translate into enhanced adaptability and efficiency, crucial for the dynamic industrial environments.

In conclusion, RoboBallet represents a pivotal shift in the realm of industrial robotics, promising increased adaptability and efficiency.

As the project evolves, addressing current limitations will further enhance its impact on the future of manufacturing.

0 Comments