Blue Jay Revolutionizes Warehouse Automation

Warehouse Automation is at the forefront of technological advancements, and Amazon’s latest innovation, Blue Jay, exemplifies this evolution.

This next-generation robotic system is designed to transform warehouse operations by integrating multiple robotic functions into a single unit.

In this article, we will explore Blue Jay’s capabilities, its potential impact on the workforce, and the cost efficiencies it promises.

As this technology is currently being tested in South Carolina, we will delve into the implications for the job market and how automation may redefine the future of logistics and delivery services.

Blue Jay Integrates Multiple Warehouse Tasks

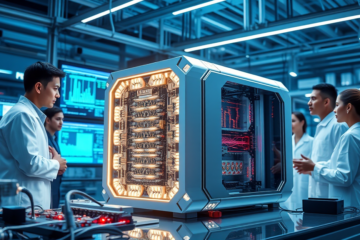

Blue Jay is an advanced robotic system developed by Amazon, designed to enhance warehouse operations by integrating multiple tasks into one efficient unit.

This innovative technology is currently being tested in South Carolina and is capable of autonomously handling approximately 75% of warehouse items, merging the functionalities of three separate robotic stations into a single streamlined platform.

With its multifunctional robotic arms equipped with suction devices, Blue Jay significantly improves operational efficiency while showcasing the potential for future automation in logistics.

Efficiency Gains and Cost Savings

Amazon’s Blue Jay robot is revolutionizing warehouse operations by combining tasks traditionally performed at separate stations into one cohesive unit.

This integration not only boosts efficiency but also leads to significant savings for the company.

The streamlined process is designed to handle approximately 75% of warehouse items autonomously, directly reducing operational costs.

Scenario Cost per Item Legacy three-station flow 0.60 USD Blue Jay single-station 0.30 USD

This cost reduction mechanism translates to substantial savings, with Blue Jay cutting expenses by approximately 30 cents per item.

Consequently, estimates suggest these savings could reach up to $4 billion by 2027. Such advancements highlight a potential shift in the job market as automation increases warehouse efficiency and profitability.

Workforce Impact and Seasonal Hiring

Amazon’s integration of the advanced Blue Jay robotic system indicates a significant shift in warehouse operations.

While this technology could enable the company to avoid hiring over 160,000 U.S. roles by 2027, it simultaneously showcases a complex interplay with their ongoing strategy to recruit 250,000 seasonal workers for the holiday rush.

This juxtaposition reveals the nuanced balancing act between technology-driven efficiencies and the necessity of workforce scalability during peak demand.

The projection to forego substantial long-term hires reflects a trend towards maximizing automation for routine tasks.

Consequently, while Blue Jay’s deployment might diminish the need for full-time positions, the demand for short-term employees persists due to the seasonal surge.

Thus, despite potential cost savings achieved through automation, temporal increases in workforce underscore the continuing role of human labor in dynamic operational landscapes.

Nevertheless, this dynamic highlights a deeper transformation within labor frameworks as Amazon navigates between technological innovation and human resources adaptability.

As their automation strategy evolves, the capacity to manage these dual objectives could define future employment models, reflecting a shift towards technology-supported but strategically human-centric operations.

Augmented Reality Glasses Enhance Delivery Routes

Amazon’s augmented reality glasses are revolutionizing delivery routes by providing sublimed navigation cues and safety alerts.

These glasses facilitate a smooth and efficient workflow, aligning seamlessly with Blue Jay’s ambitious efficiency targets.

By integrating AI-powered technology, the glasses give delivery drivers a real-time heads-up display, showcasing crucial information that enhances their capability to navigate complex routes Instantly.

The glasses offer valuable benefits for drivers through features like:

- Instant directions

- Safety alerts

- Real-time package scanning

- Hands-free operation

These features ensure that drivers can concentrate on reaching their destinations safely and on time, enhancing overall logistics efficiency.

As Blue Jay optimizes warehouse operations through advanced robotics, the AR glasses exemplify how cutting-edge technology supports human effort smoothly, offering a glimpse into a future where automation and human work converge effectively, bringing cost savings and improved service.

Automation’s Economic Outlook to 2027

The integration of Blue Jay, Amazon’s cutting-edge robotic system, along with augmented reality glasses for delivery drivers, highlights a transformative shift in automation within warehousing and logistics.

Amazon Automation Reduces Labor Needs suggests this evolution extends beyond efficiency, impacting labor dynamics significantly.

As Blue Jay manages up to 75% of warehouse items autonomously, operational processes transform, delivering notable cost benefits.

Meanwhile, the augmented reality glasses provide drivers with enhanced navigation and safety support, further streamlining the supply chain.

These advancements forecast an economic saving of $4 billion by 2027, yet they also underscore critical labor market impacts, such as potential workforce reductions.

Therefore, while the financial prospects are promising, balancing technological integration with empathetic workforce adaptation remains crucial, ensuring a sustainable equilibrium between efficiency gains and human capital considerations in this evolving landscape.

In conclusion, the introduction of Blue Jay signifies a pivotal moment in warehouse automation, promising increased efficiency and substantial cost savings.

However, its impact on employment cannot be overlooked, as this technology reshapes the landscape of the job market.

0 Comments